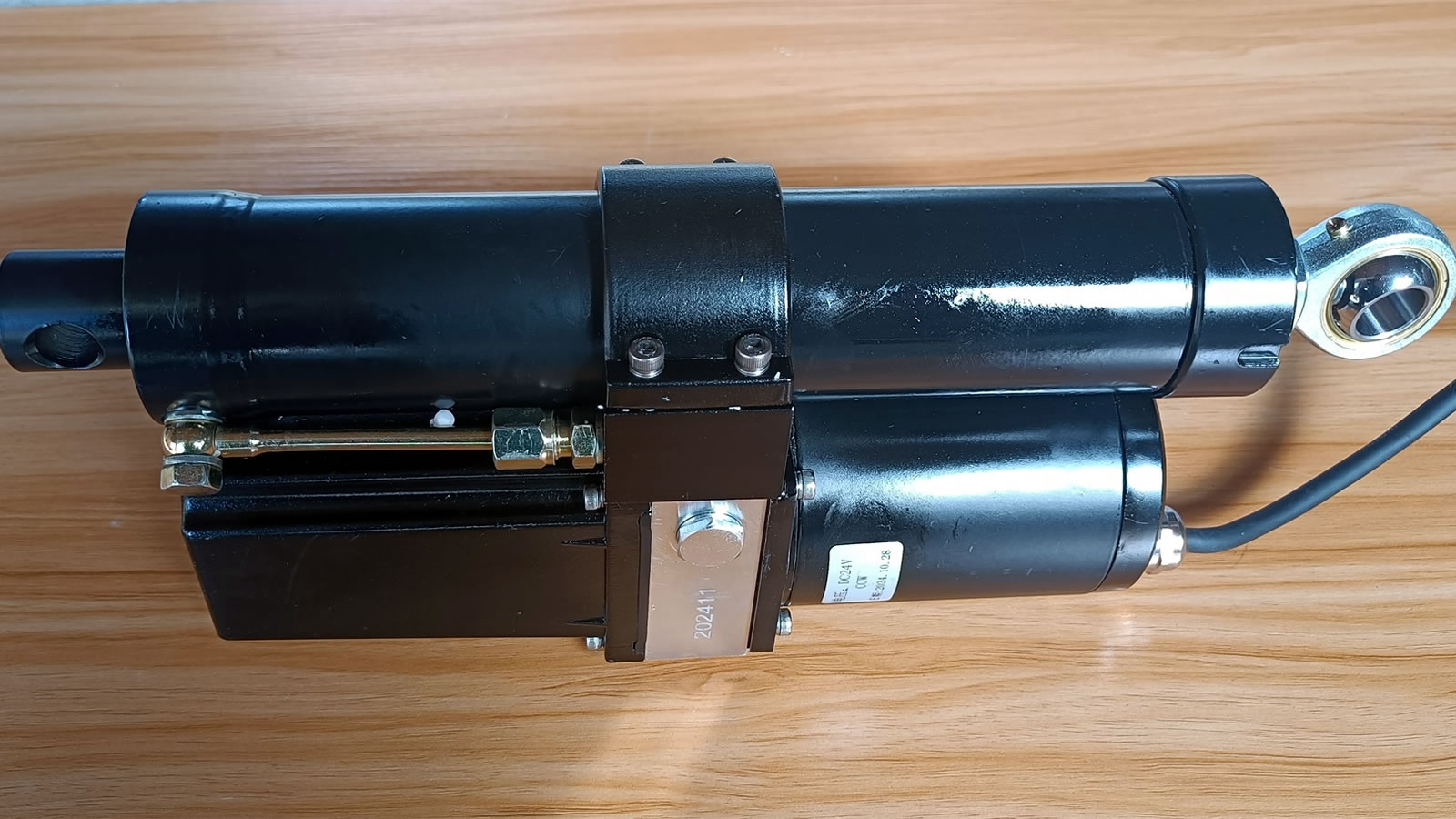

Electric Hydraulic Push Rod

Differences Between Electric Hydraulic Push Rods and Ordinary Hydraulic Push Rods

- Drive Method

Electric Hydraulic Push Rod

Driven by an electric motor that powers a hydraulic pump to generate hydraulic pressure, moving the piston rod.

Combines electrical and hydraulic technologies, often integrated and self-contained without requiring an external hydraulic source.

Ordinary Hydraulic Push Rod

Relies on an external hydraulic system (such as a hydraulic station) to provide pressure for moving the piston rod.

Typically functions as an actuator that requires connection to a hydraulic pump station via hydraulic lines. - Structure and Installation

Electric Hydraulic Push Rod

Integrates the hydraulic system and motor into a single unit, making it compact and easy to install.

Suitable for applications requiring independent operation in limited spaces.

Ordinary Hydraulic Push Rod

Simpler in structure but requires external hydraulic piping and pump stations.

Commonly used in complex and large hydraulic systems, ideal for heavy-duty operations. - Control Method

Electric Hydraulic Push Rod

Enables precise control of stroke, speed, and position via electrical signals.

Can seamlessly integrate with PLCs or other automation systems, offering high levels of intelligence.

Ordinary Hydraulic Push Rod

Control primarily depends on hydraulic valves, and complexity varies based on the hydraulic circuit design.

Precision might be slightly lower than that of electric hydraulic push rods, requiring a more complex control system. - Power Performance

Electric Hydraulic Push Rod

Provides moderate thrust, suitable for medium and small load applications.

Continuous heavy-duty operation might lead to motor overheating.

Ordinary Hydraulic Push Rod

Can deliver higher thrust and work under greater pressure, making it suitable for heavy-duty industrial applications. - Application Scenarios

Electric Hydraulic Push Rod

Used in industrial automation equipment, environmental protection equipment, medical devices, etc.

Ideal for scenarios requiring frequent starts and high control precision.

Ordinary Hydraulic Push Rod

Common in construction machinery, marine equipment, and large industrial equipment.

Best for high-load and long-duration continuous operation. - Maintenance Requirements

Electric Hydraulic Push Rod

Easier to maintain, focusing on motor and seal upkeep.

No external piping reduces the risk of oil leaks.

Ordinary Hydraulic Push Rod

Requires regular inspection of hydraulic lines, pump stations, and seals.

Greater complexity makes oil leakage or contamination a key concern.

Electric hydraulic push rods are better suited for applications requiring compactness, intelligence, and independent operation. Ordinary hydraulic push rods excel in scenarios demanding high thrust and heavy-duty performance. Choosing the right product depends on balancing performance and cost based on specific needs.

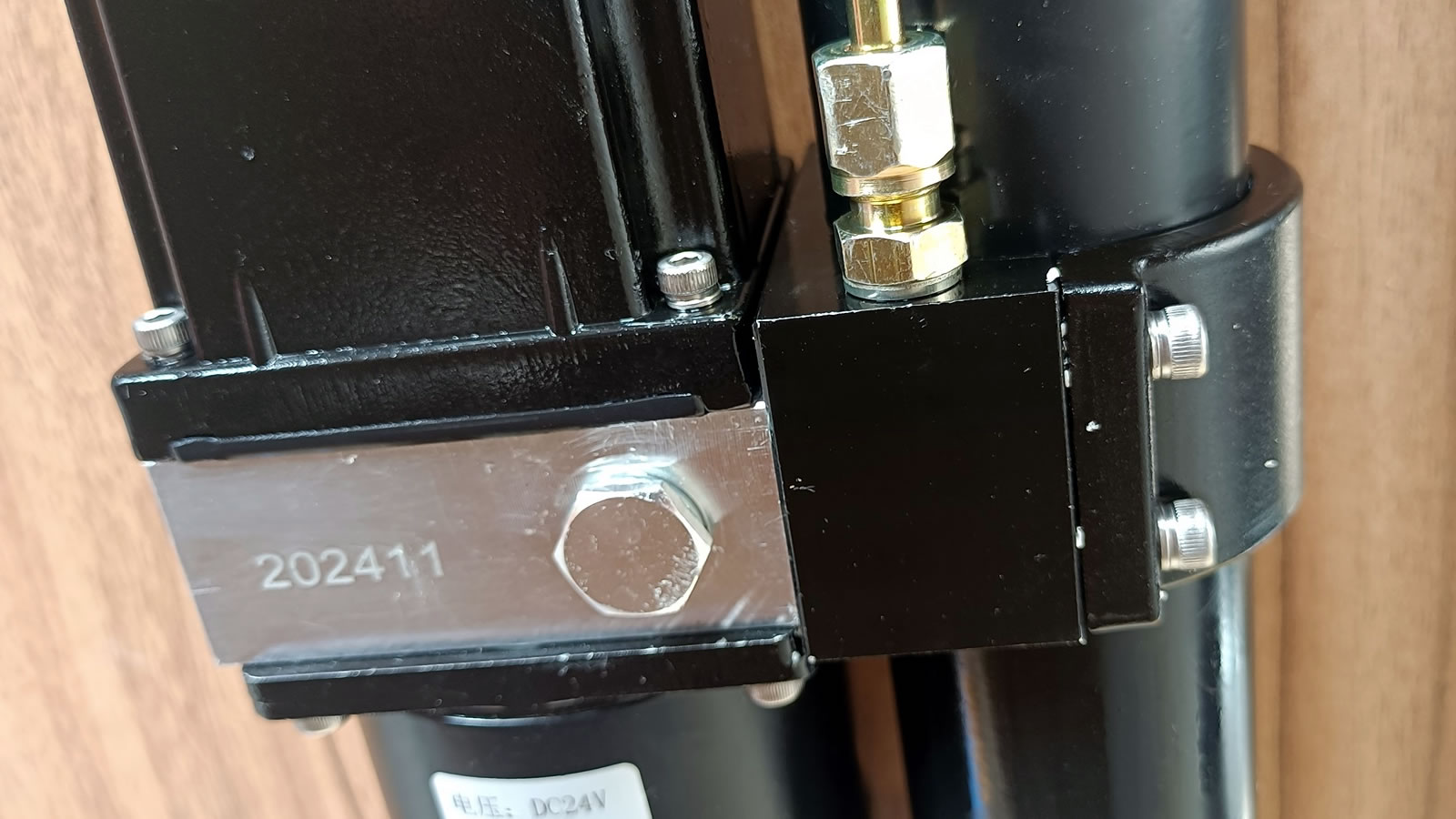

Our machines are equipped with electric hydraulic push rods, enabling remote height adjustment of attachments.

The cylinders are molded in one piece for exceptional durability and strength.

With electric control, they ensure flexibility, precision, and smooth operation.